Rail Rollers

Rail Rollers are used to move single rail length(s) or welded rail panel for different applications during maintenance and construction of railway track. We manufacture many types of Rail rollers typically for panel pulling and working around mobile flash butt welding plant/machine. We also specialise in offering customised Rail Rollers.

PRODUCT DETAILS

We manufacture many types types of Rail rollers typically for panel pulling and working with flash butt welding machine. We also specialise in offering customised Rail Rollers. All these rollers fine fabricated with workmanship and equipped with best in class original bearings.

Rail Roller - Regular : Regular Rail Roller is generally most suitable for pulling the rail panel at the time of construction. These rollers are also helpful in movement of rail lengths for leading purpose. It find application at many other locations and possibilities.

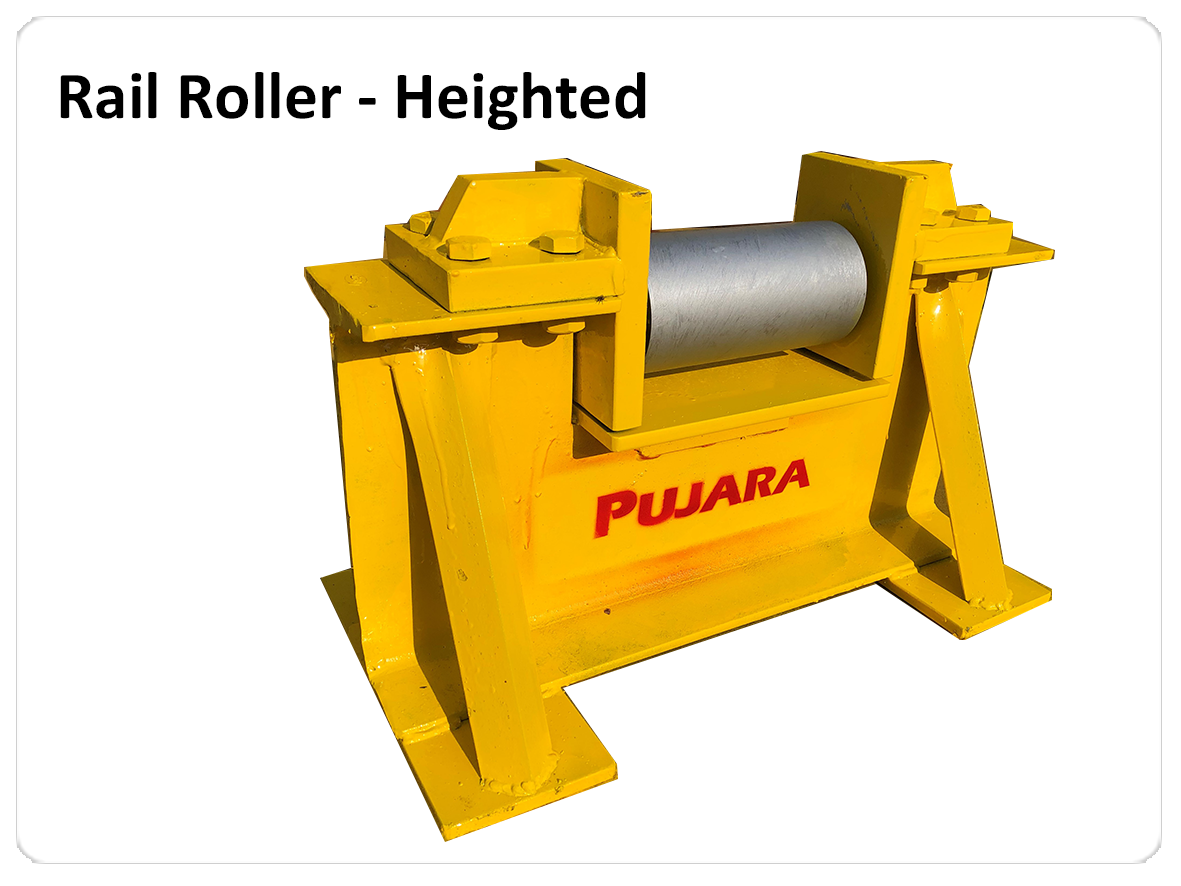

Rail Roller - Heighted : Height rail rollers are generally used with mobile flash butt welding plant. These rollers are specialised and advanced version of regular rollers wherein the construction is condusive of very hight loads and impacts. This is extremely rugged and heighted roller.

Rail Roller - Alignment Unit : Alignment unit rail roller is highly useful roller at the time of welding of panel using mobile flash butt welding machine. This is a special height adjusting roller with very rugged built and firm base.

Rail Roller - Bed : Rail roller bed generally find its application at the time of operation of mobile flash butt welding plant before laying of track on metro systems. They are very useful stacking and feeding rails.

Rail Roller - Destressing : These rollers are used to facilitate during rail destressing operation. They are generally used beneath the rail foot.

Rail Roller - Destressing Side Roller : Destressing side rollers are used to facilitate during rail destressing operation. But they are engage at neck of rail and two rollers work simultaneously to lift the rail neck (just below head).

Roller Height (from gound level) : Upto 400 mm Weight : Upto 150kg (Different as per type of roller) Compatible Rail profiles : 60kg or 52kg Type : Fixed Roller & Height Adjusting Impact/Load Capacity : Up to 1 MT Bearing Replacement : Supported